On February 2, 2025, exciting news came from the annual Ho Leung Ho Lee Foundation Awards Ceremony: Professor Xiao Changfa, leader of SUES’ Fiber New Materials Industry–Academia–Research Team, was honored with the Ho Leung Ho Lee Foundation Award for Scientific and Technological Innovation. This marks the university’s first-ever win of a major national science and technology award—a milestone achievement.The prestigious honor reflects the dedication and innovative contributions of Professor Xiao and his team, who have devoted decades to pioneering work in the field of fiber new materials. Their sustained dedication over decades has paved the way for progress in this strategic field.

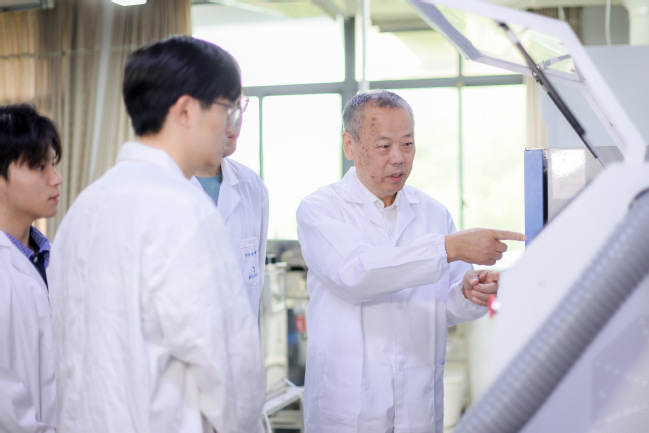

Professor Xiao Changfa, who leads the Advanced Fiber Materials Industry–Academia–Research Team, has devoted his career to fiber material innovation and industrial application. He is widely recognized as a leading figure in China’s research and development of hollow fiber membrane separation materials.Under his leadership, the team was designated a National Huang Danian–Style Teaching Team and has achieved a series of groundbreaking advances in chemical fiber forming theory and engineering applications, hollow fiber membrane manufacturing technologies, and the development of functional fiber-based materials and textiles.The team has received numerous high-level awards, including the National Technological Invention Award (Second Class), the National Science and Technology Progress Award (Second Class), the China Textile Academic Grand Prize, the China Patent Excellence Award, a Gold Medal at the Geneva International Exhibition of Inventions, and a Gold Medal at the National Invention Exhibition. Professor Xiao has authored such monographs as Preparation Methods and Applications of Hollow Fiber Membranes, Applied Fundamentals of Membrane Separation Materials, Introduction to Chemical Fibers, and Fiber-Reinforced Composite Materials. He has published more than 400 SCI/EI-indexed papers and holds over 160 granted invention patents in China and internationally.

From Breaking Monopolies to Setting Standards: The Rise of Chinese Innovation

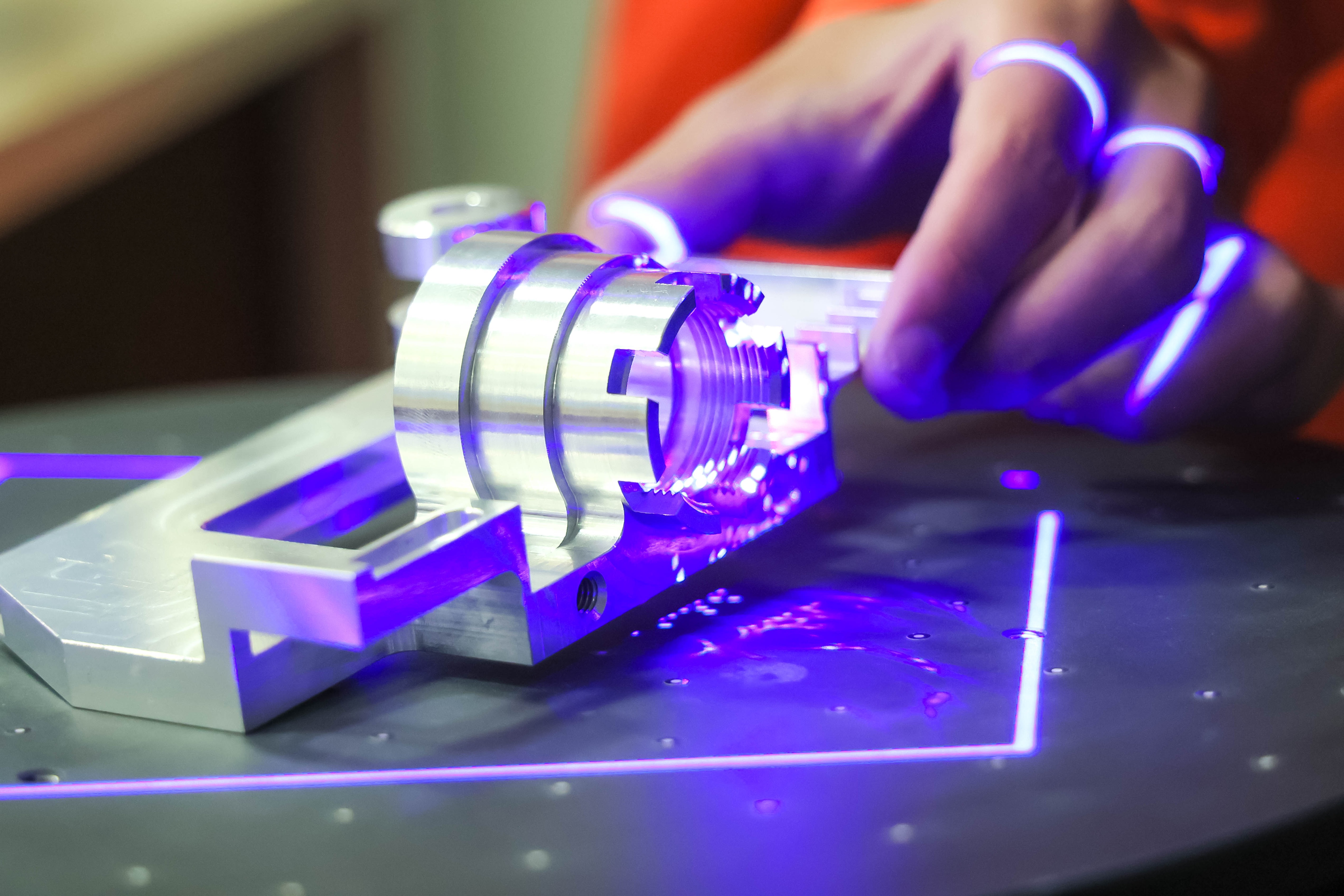

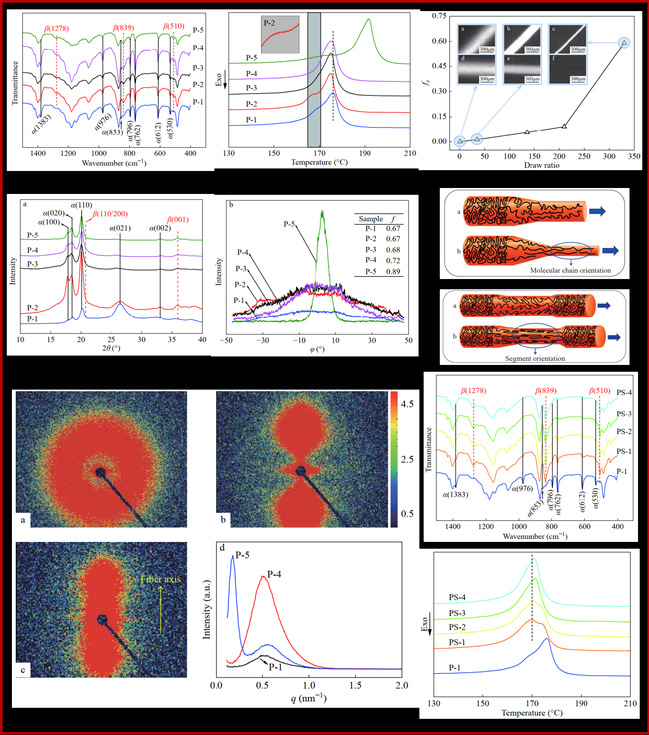

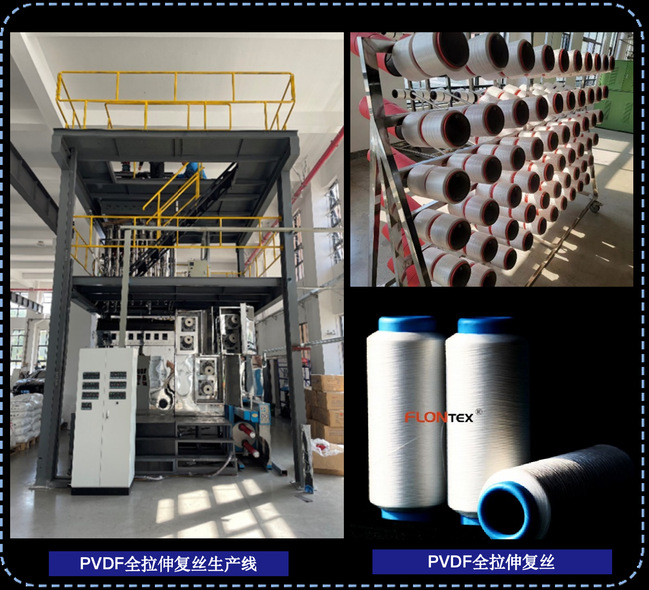

In the 1980s, after two academic visits to Japan, Professor Xiao Changfa witnessed firsthand the gap between China and global leaders in strategic materials such as high-performance fibers and separation membranes. This experience shaped his lifelong mission: to free China from dependence on foreign technology in advanced materials. Forty years of perseverance later, he and his team have redefined “Made in China”—not as a makeshift substitute, but as products that match or even surpass international standards.The team built China’s first integrated production line for fluoropolymer fully drawn yarn (FDY) fibers at a hundred-ton scale, breaking long-standing foreign monopolies. They also pioneered thermally induced phase separation (TIPS) technology for polyethylene hollow fiber reinforced membranes, producing membranes that outperform both domestic and international counterparts.Their superoleophilic-hydrophobic hollow fiber membrane and high-efficiency lubricant dehydration system was certified as “internationally leading” and designated as a Major First (Set) Technological Equipment of Shandong Province in 2025. Meanwhile, their R&D and industrialization of nano-silver hybrid antibacterial textiles achieved world-leading advances in fiber-based in-situ self-assembly of nano-silver and precise particle size distribution control.Through fundamental research and new product development, the team’s innovations—several of which have been designated National Key New Products—now help process over 10 million tons of wastewater daily across multiple countries and regions. In this sense, they have truly “written their research papers on the production line,” transforming scientific insight into tangible solutions for China’s most pressing technological challenges.

From Theory into Action: Safeguarding Rivers with Technological Innovation

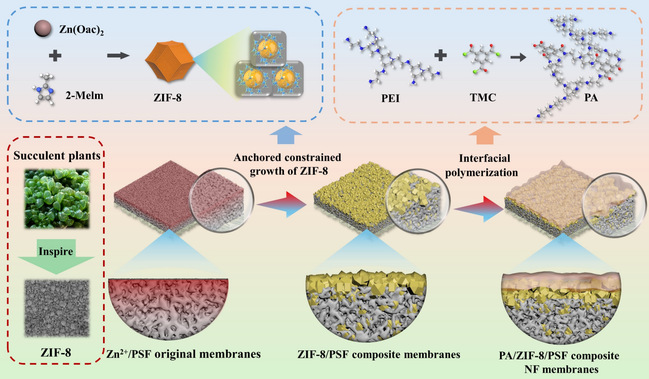

True technological innovation must reach for the highest breakthroughs while remaining firmly grounded in real-world application. The team has consistently aligned its scientific pursuits with the national mission of ecological civilization. Addressing critical national needs such as wastewater reclamation and environmental protection, they pioneered a series of original hollow fiber membrane manufacturing technologies—including pressure-responsive membrane fabrication, melt-spinning–stretching interfacial pore-forming, and integrated melt/solution online composite spinning. These practices vividly illustrate the concept that “Lucid waters and lush mountains are invaluable assets.” Tackling the difficult challenges of oily wastewater, thin oil slicks on open water, and airborne organic pollutants, the team invented fiber preparation technology incorporating cross-linked structures, leading to the development of ultrafine oleophilic/hydrophobic nonwoven fiber materials. They also pioneered integrated fiber membrane systems compatible with vessels and unmanned surface vehicles—for the continuous, efficient recovery of surface oil films and hazardous chemical spills.Today, their industrial-scale filtration and adsorption textile production lines supply products to more than 40 countries and regions, playing a vital role in oil–water separation, emergency pollutant response, air purification, and waste oil regeneration.

Nurturing Innovation Through Legacy: A Multi-Generational Force for Breakthroughs

The team has forged the spirit of “building on experience, working diligently, daring to innovate, and devoting wholeheartedly.” As a National Huang Danian-style Teacher Team in National Universities, it has cultivated outstanding talents including winners of the National May 1st Labor Medal and scholars selected for the Young Talent Support Program of the China Association for Science and Technology (CAST).The Fiber Materials Research Center, where the team is based, has been approved as the Fluoropolymer Fiber Materials Research Base and the Key Laboratory of Fiber Membrane Preparation Technology and Application in the Textile Industry.With knowledge and experience passed down through three generations of senior, middle-aged and young researchers, the team has completed or is undertaking sub-projects of the National Key R&D Program, projects of the National Natural Science Foundation of China, Jiangsu Provincial Key R&D Program, industry-university-research projects in Zhangjiagang, and cooperative programs with Sinopec, The Hong Kong Polytechnic University and other institutions. Many achievements have been transformed and applied.

From radiative cooling fibers and textiles, to membrane-based water treatment and key technologies for liquid sodium sulfate recovery in the printing and dyeing industry, to the development and application of heat- and solvent-resistant polyaramids and perfluoropolymer hollow fiber membranes, the team has never stopped innovating.

Guided by the conviction that their research should serve national needs, the team remains committed to translating scientific achievement into tangible societal progress. It continues to dedicate itself to the mission of “applying scientific and technological outcomes to the great cause of modernization,” contributing actively to China’s pursuit of high-level technological self-reliance and the national strategy of innovation-driven development.